Bloques vs. Ladrillos rojos tradicionales

Feb 15, 2026

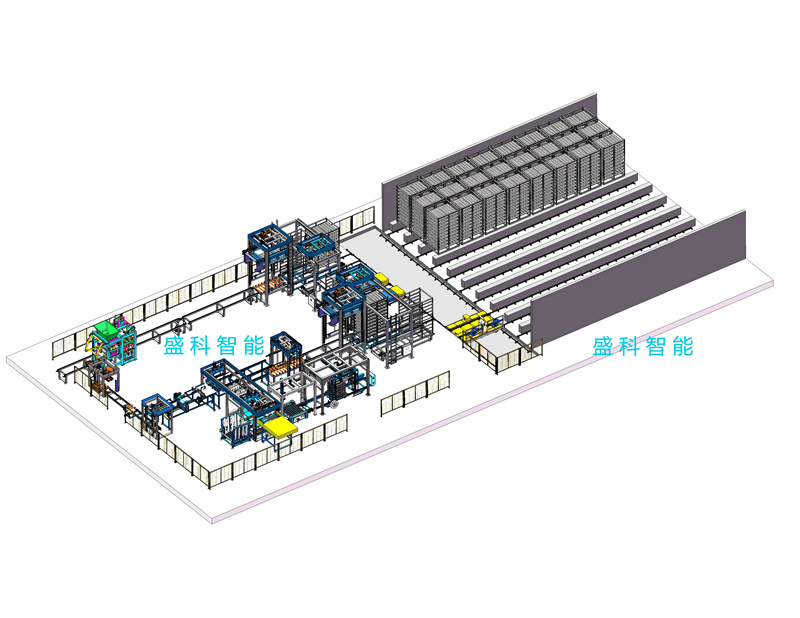

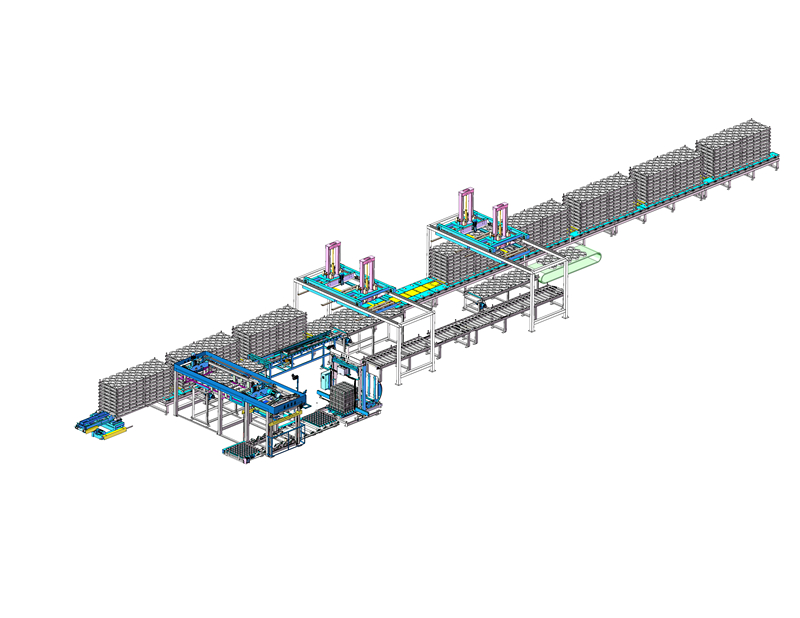

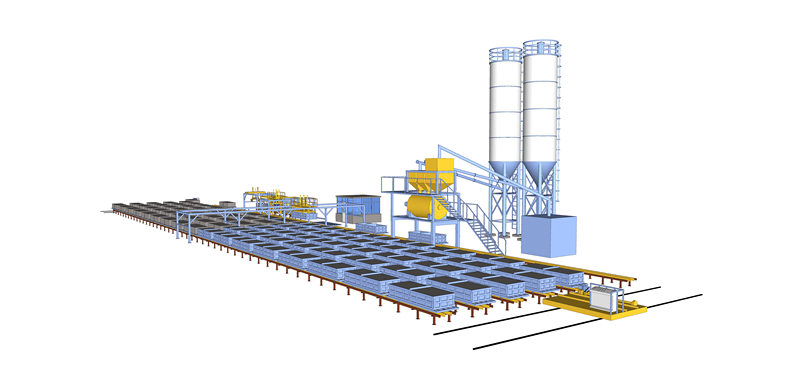

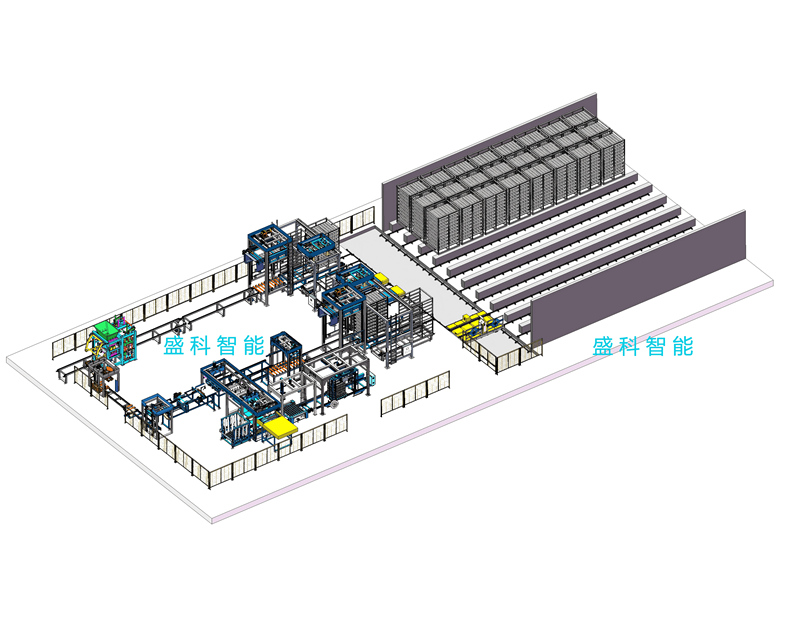

Al planificar un proyecto de construcción, una de las decisiones más importantes es elegir el material adecuado para las paredes. Durante siglos, el debate era simple: los ladrillos de arcilla roja eran la opción preferida. Sin embargo, el panorama de la construcción moderna ofrece alternativas atractivas, principalmente diversos tipos de bloques de hormigón. Este artículo proporciona una comparación técnica y accesible entre los ladrillos rojos tradicionales y los bloques modernos y, lo que es más importante, presenta cómo Quanzhou Senko Intelligent Equipment Manufacturing Co., Ltd. permite a los fabricantes producir bloques de alta calidad que superan a los materiales tradicionales en casi todas las métricas. Parte 1: Los contendientes: ladrillos rojos vs. bloques modernos Para entender por qué está cambiando la industria, primero debemos analizar las características de cada material. Ladrillos rojos tradicionalesEl material de construcción clásico, elaborado a partir de arcilla moldeada y cocida en hornos. Ventajas: Poseen buena resistencia a la compresión y masa térmica (absorben el calor lentamente). Su rendimiento es bien conocido por los albañiles tradicionales.Desventajas: La calidad puede ser inconsistente debido a las variaciones en las temperaturas de cocción. Son más pequeños, lo que requiere más mano de obra y mortero. Fundamentalmente, su producción consume tierra fértil y emite cantidades significativas de CO2, lo que genera graves problemas ambientales. Bloques de hormigón modernos (macizos, huecos y AAC)Esta categoría incluye bloques de hormigón macizo, bloques huecos y bloques de hormigón celular curado en autoclave (AAC). Ventajas: Su tamaño y resistencia son uniformes, y su mayor formato agiliza la construcción. Pueden diseñarse para fines específicos, como aislamiento o soporte de carga.Desventajas: Los bloques de hormigón macizo pueden ser pesados y tener un aislamiento natural deficiente. Los bloques de AAC, si bien son excelentes para el aislamiento, son más frágiles. Parte 2: Comparación directa Colocados uno al lado del otro, las ventajas de los bloques modernos se hacen evidentes: Sostenibilidad ambiental: La fabricación de ladrillos rojos agota la capa fértil del suelo. En cambio, los bloques modernos suelen utilizar subproductos industriales como cenizas volantes o escorias. Los bloques de AAC, por ejemplo, se consideran un material de construcción ecológico, ya que no son tóxicos y pueden incorporar materiales reciclados.· Rapidez y eficiencia de construcción: Dado que los bloques son significativamente más grandes que los ladrillos rojos estándar, cubren más área por unidad. Esto se traduce en tiempos de construcción más rápidos y un menor consumo de mortero.Rendimiento estructural: Contrariamente a la creencia de que los ladrillos son más resistentes, se ha comprobado que los bloques de AAC poseen una resistencia a la compresión comparable o incluso superior a la de los ladrillos de arcilla tradicionales en algunas aplicaciones, con un peso de tan solo un tercio del de los ladrillos tradicionales. Esto reduce la carga muerta sobre la cimentación del edificio, lo que permite ahorrar en acero y hormigón.Rentabilidad: Si bien el costo unitario puede variar, el costo total del proyecto puede ser entre un 15 % y un 20 % menor con bloques de AAC debido a una instalación más rápida, menor manipulación de materiales y menores requisitos estructurales. La forma uniforme también requiere un yeso más delgado, lo que ahorra en materiales de acabado.· Precisión: Los bloques modernos ofrecen un acabado simétrico y uniforme, lo que mejora la pulcritud estética de la estructura y garantiza una calidad consistente de la que a menudo carecen los ladrillos cocidos. Parte 3: La ventaja de Senko: convertir materias primas en bloques de primera calidad Aquí es donde la experiencia de Quanzhou Senko Intelligent Equipment Manufacturing Co., Ltd. cobra importancia crucial. Reconocer la superioridad de los bloques es una cosa; fabricarlos de forma consistente, eficiente y rentable es otra. Desde su fundación en 2017, Senko se ha posicionado a la vanguardia de esta transformación industrial. Como Empresa Nacional de Alta Tecnología, con 7 patentes de invención y más de 30 patentes de modelos de utilidad, Senko proporciona la "sala de máquinas" para la fábrica de bloques moderna. Así es como Senko facilita la transición de los ladrillos tradicionales a los bloques avanzados: 1. Líneas de producción automatizadas para una calidad constantePara lograr la uniformidad que distingue a los bloques de los ladrillos, se necesita ingeniería de precisión. Senko fabrica un conjunto de equipos inteligentes avanzados, que incluyen apiladoras de ladrillos, laminadoras y empacadoras. Esta automatización garantiza que cada bloque producido cumpla con las especificaciones exactas, eliminando las inconsistencias de "quemado excesivo o insuficiente" de los hornos tradicionales. 2. Convertir los residuos en riqueza (Reciclaje de residuos sólidos)Uno de los mayores argumentos ambientales contra los ladrillos rojos es el consumo de arcilla virgen. Senko aborda este problema con soluciones innovadoras para el reciclaje de residuos sólidos. Sus líneas de producción enmarcadas y líneas multicapa de mantenimiento de residuos sólidos están diseñadas para procesar subproductos industriales. Esto permite a los clientes de Senko fabricar bloques de alta calidad a partir de materiales reciclados, convirtiendo los desafíos ambientales en oportunidades de negocio rentables. 3. Soluciones de alta gama para una estética modernaEl mercado está evolucionando más allá de los simples bloques grises. Existe una creciente demanda de acabados arquitectónicos. Senko ha creado soluciones exclusivas de alta gama específicamente para la producción de ladrillos antipiedra. Esto permite a los fabricantes producir bloques que imitan el aspecto de la piedra natural, obteniendo un mayor valor en el mercado en comparación con el ladrillo rojo estándar. 4. Fabricación impulsada por la innovaciónEl compromiso de Senko con la I+D permite que sus clientes se beneficien de tecnología de vanguardia. Sus soluciones automatizadas, que incluyen nuevos vehículos de transferencia de energía, optimizan el proceso de producción, desde la mezcla y el moldeo hasta el curado y el envasado. Este enfoque holístico garantiza el máximo rendimiento y la mínima generación de residuos. Conclusión Los datos son claros: para la construcción moderna que prioriza la velocidad, la sostenibilidad, la rentabilidad y el rendimiento estructural, los bloques de hormigón y AAC ofrecen ventajas significativas sobre los ladrillos rojos tradicionales. Sin embargo, capitalizar este cambio de mercado requiere la tecnología adecuada. Quanzhou Senko Intelligent Equipment Manufacturing Co., Ltd. ofrece las soluciones integrales, innovadoras y automatizadas necesarias para producir bloques de primera calidad. Ya sea que el objetivo sea crear bloques ligeros de AAC, unidades de mampostería de hormigón macizo o piezas arquitectónicas de alta gama anti-piedra, las tecnologías patentadas y las líneas de producción llave en mano de Senko permiten a los fabricantes construir mejor y construir para el futuro. Para obtener más información sobre cómo Senko puede automatizar su producción y ayudarlo a liderar el mercado de materiales de construcción sustentables, visite sus canales oficiales o comuníquese con su equipo de ventas para una consulta. https://www.senkomachine.com/productos